- What is SIP?

- Development of Circular Economy System

- Project outline

Development of Circular Economy System

What is Circular Economy?

The Circular Economy is an economic model that aims to maximize the value of resources and products, minimize resource use, and reduce waste and CO2 emissions. In addition to the traditional 3Rs (reduce, reuse, recycle), it focuses on the creation of closed-loop systems in which products, materials, and resources are reused, repaired, refurbished, and recycled for as long as possible. This approach contrasts with the conventional linear "take, make, waste" economy based on mass production and mass consumption, which has not only generated massive amounts of waste and hindered appropriate material cycles but has also caused various environmental problems such as climate change, depletion of natural resources, and destruction of biodiversity due to large-scale resource extraction. Therefore, it is extremely important to shift to a "circular economy" that uses resources in a sustainable manner.

Plastic Issues

About plastics

Plastics are synthetic resins made primarily from petroleum that are lightweight, easy to process, and inexpensive. Since the invention of plastics by a Belgian-American chemist Baekeland in 1907, and with the development of the petrochemical industry, the global production of plastics reached 413.8 million metric tons in 2023. Source: Statista, Global plastic production (2025)

Residual plastics in the environment

Many plastics that are not properly disposed of remain in the environment for extremely long periods of time, causing a variety of problems. For example, plastics in the ocean threaten marine life and have a significant impact on the fishing, aquaculture and tourism industries. According to the OECD, this plastic pollution is estimated to cause economic losses of 13 billion dollars (1.43 trillion yen) per year worldwide. The amount of plastics used continues to increase every year, and the Ellen MacArthur Foundation claims that by 2050 there will be more plastics than fish by weight.

Current Status of Plastic Recycling in Japan

In Japan, most discarded plastics are incinerated, and the heat generated in the process is recovered and effectively utilized (thermal recovery). However, since most plastics are made from petroleum, a fossil fuel, the limited fossil resources are still being "consumed," and thermal recovery tends not to be considered "recycling" in the world. In addition, a large amount of CO2 is generated in the process, which is undesirable from the perspective of global warming prevention, etc.

The 3rd term of SIP: Development of Circular Economy System

Outline

This SIP project focuses on the development of a circular economy system for plastics whose use is expected to increase in the future, through the following research and development themes.

R&D Themes & Structure

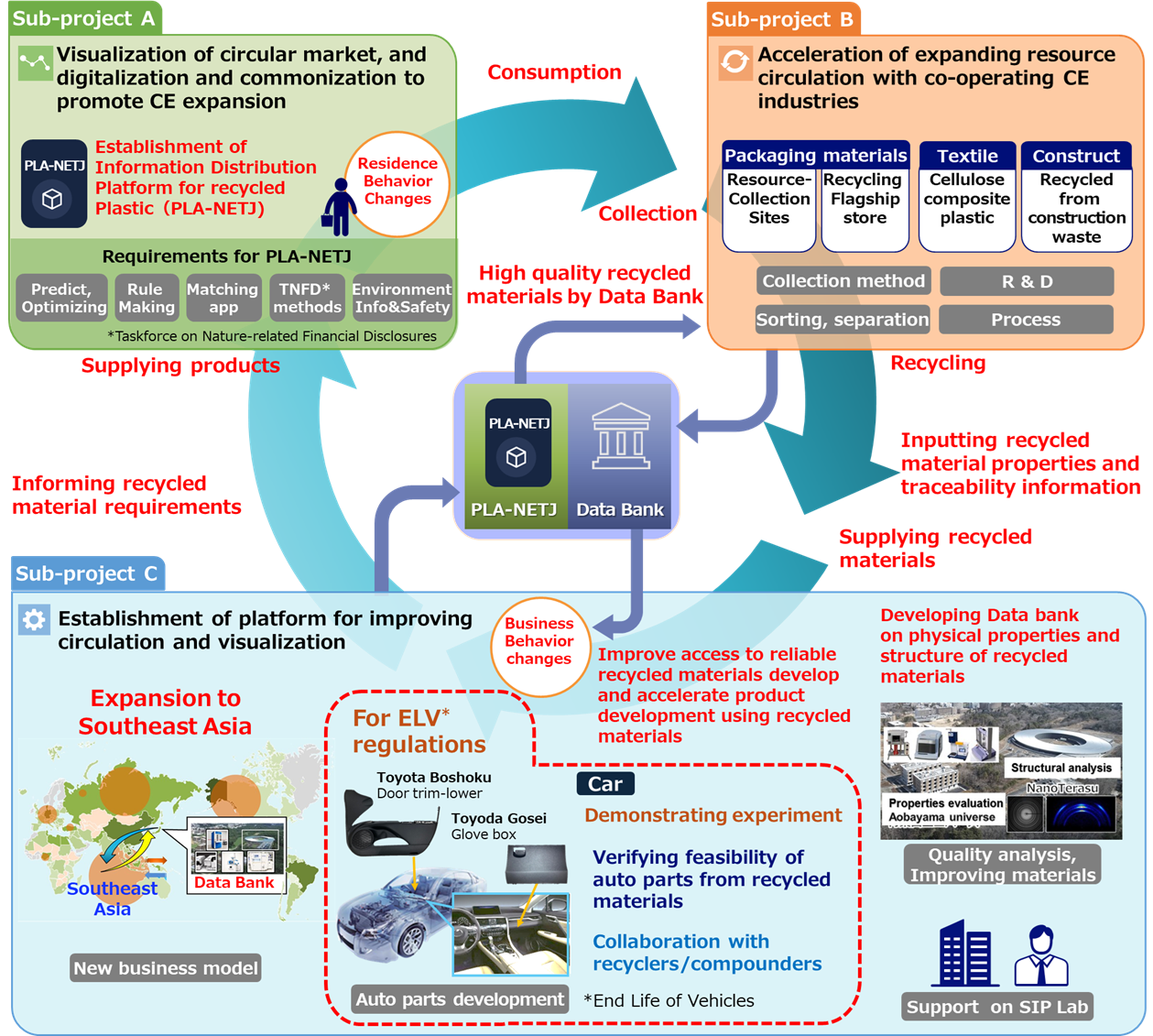

The following subprojects A to C aim to build a circular economy system in cooperation with the other.

Sub-project A

Visualization of circular market, and digitalization and commonization to promote CE expansion

Establish a platform called PLA-NETJ to share information about plastics in the market. This platform will help visualize data and set rules for sharing information. It will also connect the flow of materials, production, distribution, usage, sorting, and recycling with digital data to encourage the usage of recycled plastics. The system promotes the usage of recycled plastics.

- A1:

- Build a digital infrastructure that contributes to the expansion of the circulation market (Development of PLA-NETJ system).

- A2:

- Organize and standardize the information rules necessary to build a digital infrastructure.

(Establish standards for information to be disseminated by PLA-NETJ). - A3:

- Develop and visualize natural capital assessment tools (develop natural capital risk and environmental assessment methodology and work with PLA-NETJ).

Sub-project B

Acceleration of expanding resource circulation with co-operating CE industries

Create a system for sorting and supplying used and collected plastics with municipalities. This will provide a dependable and affordable source of high-quality recycled materials. It will also enhance cooperation between manufacturers and recyclers, increasing the availability of recycled plastics from textiles, clothing, and construction materials that have a high potential for recycling.

- B1:

- Develop a system for sorting and supplying high-grade recycled materials from used plastics (advanced sorting and data visualization of recycled materials)

- B2:

- Establish a system to sort and supply plastics collected in cooperation with municipalities (increase supply of high-quality recycled resources through cooperative collection by municipalities).

Sub-project C

Establishment of platform for improving circulation and visualization

Develop a database for recycled materials by collecting and analyzing data on the physical properties of recycled plastics using advanced technology in Japan. Collaboration between industry, universities, and the government will set standards and use this data to verify and certify recycled materials. For ELV regulations, SIP aims to produce high-quality recycled materials for vehicle parts.

- C1:

- Develop a platform to improve circulation and visualization (Environmental testing, diagnosis,

tracer development and accumulation of recycled material data, development of vehicle parts

using recycled materials ) - C2:

- Evaluate recycled material quality and develop vehicle parts (quality evaluation and parts

development by Tier1 companies, etc.) - C3:

- Share SIP results in Southeast Asia (Development of a business model necessary to expand the use of recycled materials)