A3-02 Development of environmental assessment method for plastic resource recycling system

Principal Investigator

GENCHI Yutaka (National Institute of Advanced Industrial Science and Technology)

Research and Development Overview

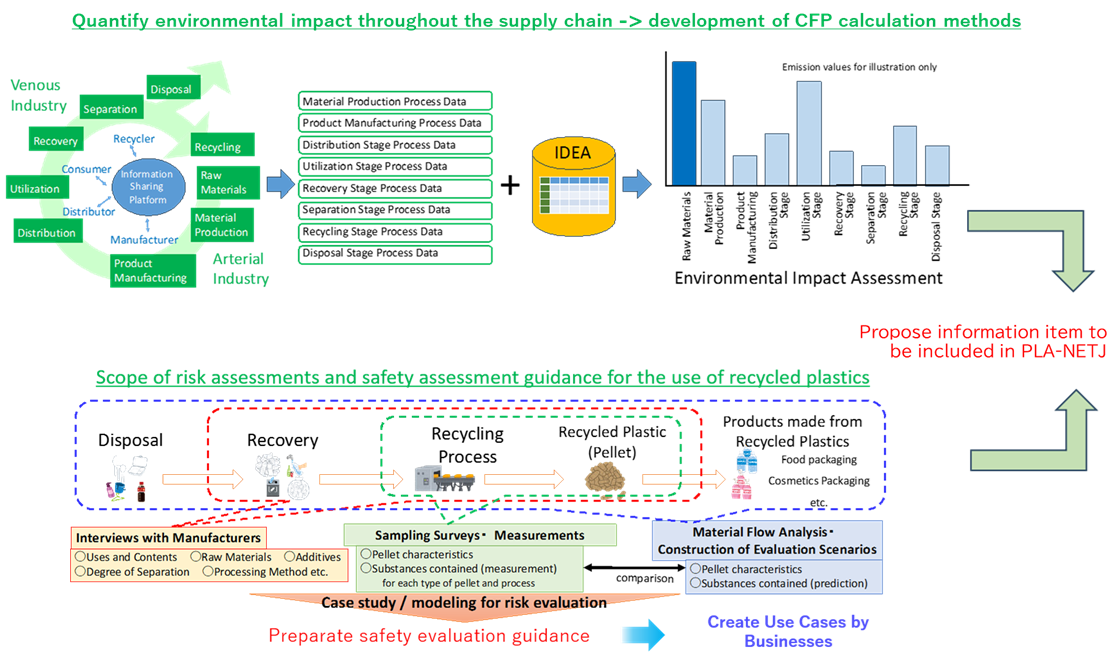

In this research project, we collect key environmental and safety information on the characteristics of recovered plastics and processes for recycling them. Based on this information, we propose a method for calculating the carbon footprint (CFP) of the entire supply chain. Finally, we study how this information can be included in PLA-NET J with the aim of contributing to the social implementation of a circular economy.

For risk assessment, we identify additives, impurities, and contaminants in recycled plastic pellet samples (20 or more samples) and establish the maximum acceptable exposure levels for potentially hazardous substances. Additionally, we select one or more recycled plastic products in which polypropylene (PP) is the main polymer and develop a use scenario for a case study on exposure and risk assessment.

Figure.1 Overview of Research and Development

Research Contents

1. Data collection and calculation of inventory data

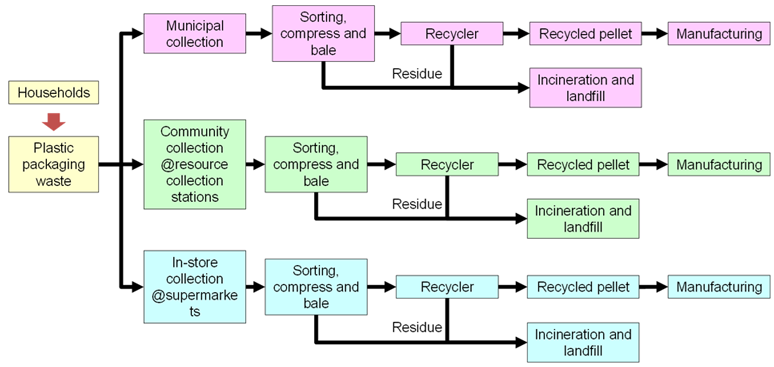

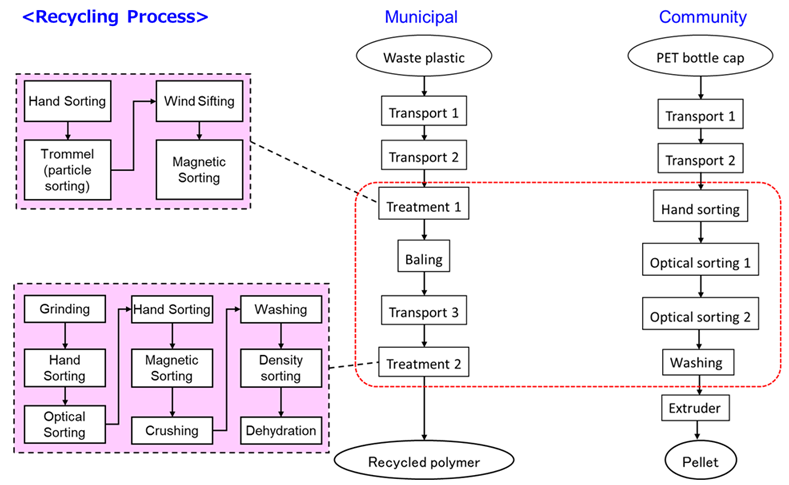

We collected operational data on the collection and treatment processes for plastic packaging waste from households in Kobe City of Japan, through interviews with local governments and private companies, on-site surveys, and literature surveys.

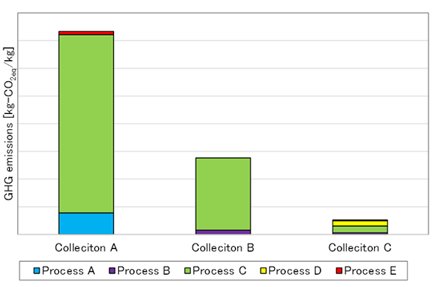

We calculated and compared the CFP of each collection route such as municipal collection, community collection, and in-store collection.

Figure.2 System boundary of each collection route

Figure.3 Calculated inventory data

2. Case study of CFP

We conducted a web-based survey targeting 1,652 Kobe citizens to investigate the actual situation regarding the separation and cleaning of plastic packaging waste.

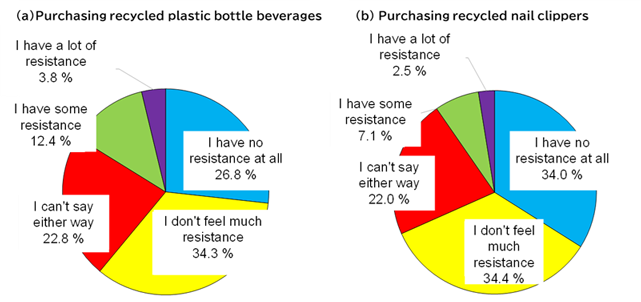

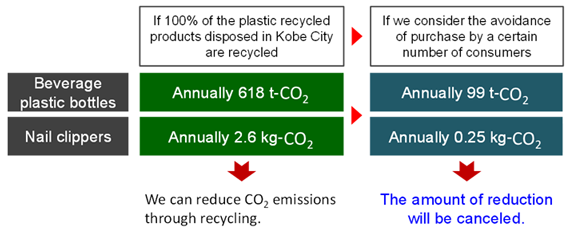

We investigated the attitudes towards purchasing products made from recycled plastic packaging waste, and we discussed how those attitudes may affect the reduction effect on CFP.

Figure.4 Resistance to purchasing products made from recycled plastic packaging waste: (a) an example of a product that comes into direct contact with the mouth and (b) an example of a hygiene product

Figure.5 The impact of avoiding the purchase of beverage plastic bottles and nail clippers made from recycled plastic packaging waste on the CFP reduction effect

3. Acquisition of process data of waste plastic recycling

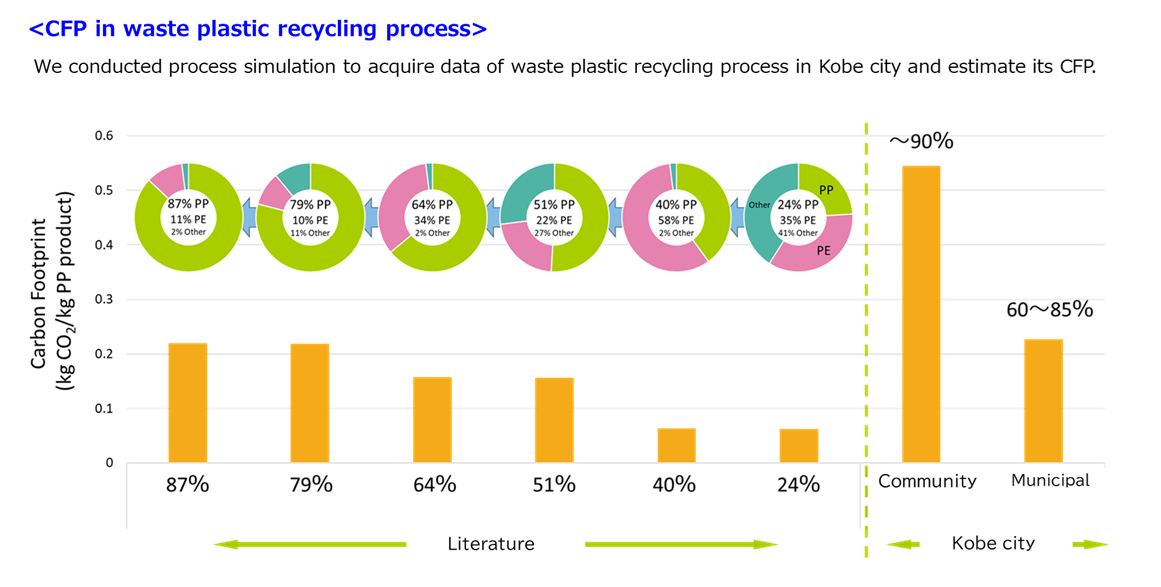

We conducted process simulation to acquire data of waste plastic recycling process in Kobe city and estimate its CFP.

Figure.6 Waste plastic recycling process in Kobe city

Figure.7 CFP in waste plastic recycling process

4. Identification and quantification of substances in recycled plastics

We investigated the selection of priority substances to be analyzed, the selection of solvents for extracting additives, and the dissolution method for additives, impurities, and contaminants contained in recycled plastics. As a result, we confirmed that additives in plastics can be extracted efficiently using a method that involves heating with cyclohexane at 140°C for 4 hours, followed by resin resuspension via methanol transfer and concentration by nitrogen blowing. Using this method, we analyzed the plasticizers (12 phthalate esters, 7 alternative plasticizers) and flame retardants (7 phosphate esters) contained in recycled plastic pellets, and we analyzed the additive content by origin and cleaning method. The total amount of plasticizers was less than 0.03% of the recycled plastic pellets, and the concentration of organophosphorus flame retardants was even one or two orders of magnitude lower. We are also analyzing UV absorbers and antioxidants.

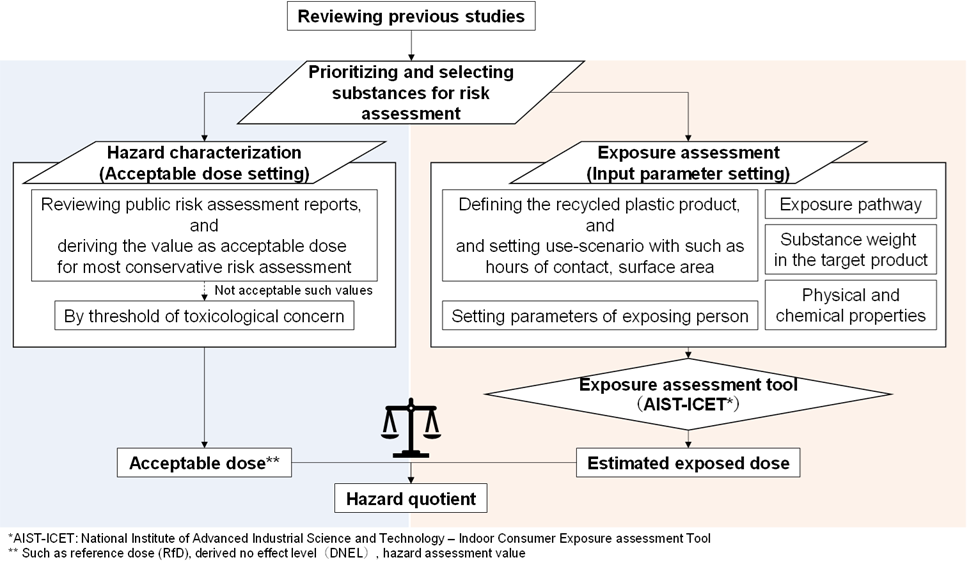

5. Case study of risk assessment of hazardous substances in recycled plastics

We present the framework for the current risk assessment in Fig. 8. Our risk assessment utilizes the hazard quotient as an initial screening method, which compares the estimated exposure of a target substance with its acceptable dose. If the estimated exposure is lower than the acceptable dose, the hazard quotient is also below 1, indicating that the substance's risk is considered acceptable. In the current case studies, we selected substances regulated under the RoHS directive* that are of high interest to nearly all companies involved in the import and export of plastics. As sample polypropylene products under SIP, we chose (1) the plastic holder of nail clippers and (2) plastic button panels used for opening and closing car windows. We established use scenarios by considering factors such as contact duration and surface area for both target substances and products, then set the necessary parameters for the exposure assessment tool. To determine substance concentrations in recycled plastic products, we reviewed approximately 100 previous studies analyzing these substances and applied the highest measured concentrations from these studies in our exposure assessment. Even under conservative risk assessment conditions—accounting for all combinations of products, scenarios, and substance concentrations mentioned above—the estimated exposures did not exceed the acceptable dose. Therefore, we conclude that the health risks associated with these substances in recycled plastics are negligible.

* The RoHS (Restriction of Hazardous Substances) Directive

Figure 8. Risk Assessment Framework for current case studies.