B1-03 Building a data-driven advanced sorting system

Principal Investigator

ISEKI Yasuto (Mitsubishi Electric Corporation)

Background and purpose

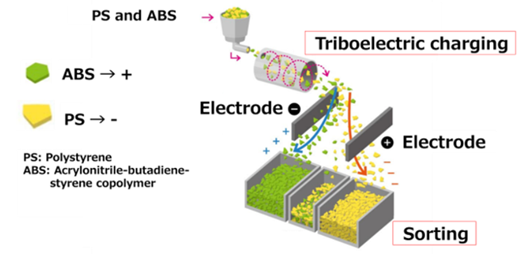

- “Electrostatic separation” is an advanced plastic sorting technology that achieves high purity by utilizing differences in triboelectric charging characteristics of materials (Fig.1).

- Self-developed electrostatic separation equipment is in operation in Mitsubishi Electric Corporation appliance recycling plant.

- It can efficiently sort various plastics, not only home appliances.

Build a data-driven “Smart Electrostatic Separation” system for stable supply of high-quality recycled plastic.

Fig.1 Principle of electrostatic separation

(Example of our home appliance plastic recycling)

Research and Development Overview

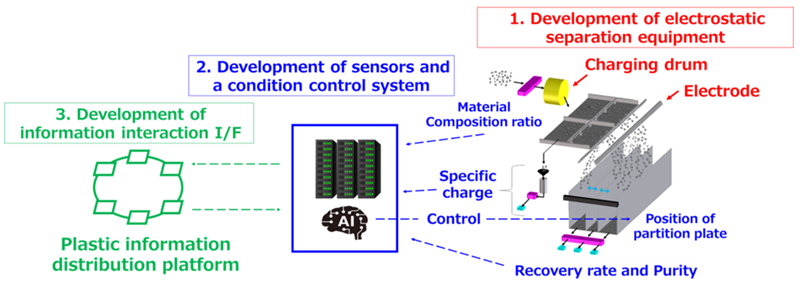

- IoT sensors monitor factors of electrostatic separation and AI controls sorting conditions (Fig.2).

- Plastic materials of any compositions can be automatically and optimistically sorted.

Fig.2 Data-driven electrostatic separation equipment

Progress and Achievements

We have developed a verification equipment of electrostatic separation that can automatically sort mixed plastics according to changes in composition ratio. The hyperspectral camera installed in the verification equipment can identify the type of plastic with 99% accuracy and visualize the composition ratio of plastics before and after sorting in real time.

In addition, originally developed specific charge distribution evaluation system can sense the specific charge of plastics with high accuracy. By having AI learn the composition ratio of plastics before and after sorting and the specific charge distribution, it is possible to automatically calculate sorting conditions with higher purity.