C1-01 Development of environmental testing, diagnosis, and tracer technologies and digital analysis platform for industrial applications

Principal Investigator

NAITO Masanobu (National Institute for Materials Science)

Research and Development Overview

- Mission 1: Build a digital platform for information sharing

- Establish a research and development base for CE (Circular Economy) plastic materials as the CE-SIP lab at the National Institute for Materials Science (NIMS) and build a digital analysis base to promote collaborative research between industry, government and academia related to CE and strengthen industrial competitiveness.

- Mission 2: Develop technology to realize arteriovenous and venous-arterial collaboration

- Promote collaboration between recycler and manufacturer for the circular economy by establishing tracer molecules and odor identification and detection technology for recycled materials.

- Mission 3: Develop technology and create an environment to promote innovative circulation in the circular economy

- Develop circular materials based on network polymers with dynamic cross-linking structures. Also, establish environmental testing and diagnostic technology using material informatics, and tracer technology to track the sustainability of plastic products.

Carry out research and development on circular economy materials for automotive plastics to meet sustainability requirements in automobile design and end-of-life vehicles (ELV) management.

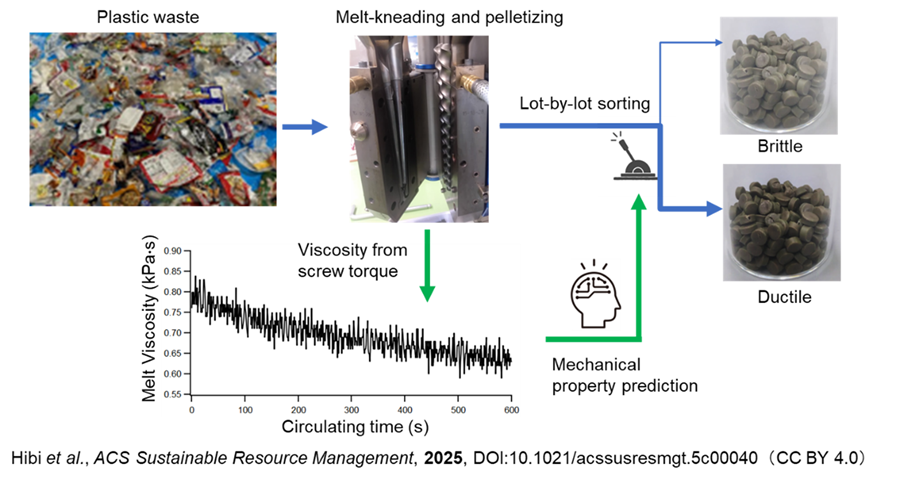

Highly Accurate Prediction from Melt Viscosity: A Zero-Cost Quality Inspection Method for Recycled Plastics

Recycled plastics typically exhibit substantial quality variations, making it difficult to classify lots based on quality without costly chemical analyses or mechanical tests performed individually for each lot. Consequently, such recycled materials have traditionally been restricted to low-value applications. To overcome this limitation, we propose a "zero-cost inspection method" that accurately predicts the mechanical properties of plastic pellets during production, solely from melt viscosity data naturally obtained in standard recycling processes.

Using deep learning, tensile strength and impact resistance were predicted with over 85% accuracy, allowing high-quality pellets to be selected prior to actual pelletizing. This approach enables even household plastic waste, conventionally destined for low-quality uses, to be upcycled into higher-value applications, thereby greatly accelerating the establishment of a sustainable, resource-circulating society.