C1-04 Automotive parts evaluation and development for the recycled material use

Principal Investigator

TSUGE Motoki (Toyota Boshoku Corporation)

Research overview

In response to the urgent issue of the End-of-Life Vehicles (ELV) Regulation*1 proposal, we will develop prototypes of automotive parts using high-quality recycled materials developed by the SIP participating organizations. Adapting recycled materials to automotive parts is extremely challenging due to the strict safety and reliability requirements. By identifying issues and presenting solutions in the SIP, we aim to propose a business model for the circular economy of plastics in our country and contribute to strengthening industrial competitiveness.

*1 End-of-life vehicles regulation: New rules for the design and end-of-life management of vehicles aim to protect the environment, decarbonize production and reduce raw material dependencies, benefiting EU industries.

Progress and results

We presented the target values for physical properties to the compounders of the SIP participating organizations, first selected the raw materials as a “quick flow” and presented the physical properties of the recycled materials obtained by adjusting the materials (compound) independently by the compounders, and compared the physical properties measured by Toyota Boshoku to identify issues for adaptation to the “door trim lower” of automotive parts at the current stage. One type of material was selected to be used for molding prototypes for the next stage, product performance evaluation.

The selected materials are made by adding 25% of recycled PIR*2 materials, and all of the target values of evaluation items (odor, VOC*3, light resistance test, glass haze, flammability, high-speed surface impact resistance) that meet the target values of physical properties and lead to product performance are also satisfied.

*2 Post Industrial Recycled

*3 Volatile Organic Compounds

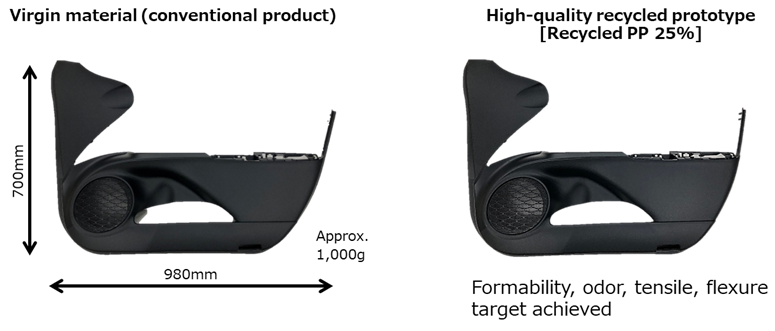

In the molding prototype, molding is performed under the same molding conditions as the virgin material used in mass production. This recycled material could be continuously molded under almost the same conditions as the molding conditions in mass production. The coloring used the same coloring masterbatch as the mass production, and almost the same appearance as the mass-produced product was obtained. (Figure 1)

Figure 1. Door trim lower

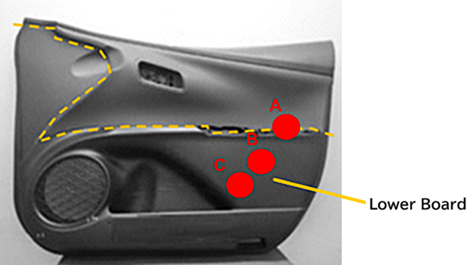

Next, we evaluated the performance in the product state. There are four evaluation items: door trim single impact test, heat resistance test, cold heat repetition test, and drop weight impact test. All of them met the criteria and passed.

Figure 2 below shows the impact area of the door trim impact test, which is the most stringent test in product performance. In order to confirm the impact on the occupants of automobile parts against the impact of a side collision from the outside of the vehicle, the impact input area to the lower board is defined as shown in Figure 2, and the change in input load and the destruction status of the product are checked. A assumes an effect on the abdomen, B and C on the lumbar region.

Figure 2. Door trim single impact test

Although the recycled PP is PIR, we were able to demonstrate the possibility of using recycled materials for automobile parts by satisfying the product performance of the door trim lower with a material to which 25% recycled material is added.

In order to further expand the qualitative and quantitative base, materials using PCR*4 materials were re-adjusted (compounded) with a compounder that had not have reached molding prototypes due to problems with some of the evaluation items that lead to physical property targets or product performance in the “quick flow” and material evaluation. The recycled material ratio was 20% and 25%, but both satisfied the target values for physical properties and the target values for evaluation items that lead to product performance. It is presumed that both materials are the result of improvements with an emphasis on impact resistance through feedback of the “quick flow”. In addition, in the use of PCR materials, we had estimated that odors and VOCs would be major issues, but the results showed that the target values were satisfied and that they could be applied to automotive interior parts.

*4 Post Consumer Recycled

This time, we evaluated the door trim lower, which has a relatively high hurdle in terms of performance among interior parts, but since the product performance was satisfied, it is easy to adapt to parts with relatively lower hurdles than door trim lowers.